We use cookies to enhance your experience. Read our policy so you can understand the types of cookies we use, the information we collect using cookies and how that information is used.Privacy Policy

Close

Confirm choices

Even though finger joint has a number of demerits in the actual performance, it is largely used due to its low noise emission and therefore comparatively comfortable driving experience.

Details

IEC Finger Expansion Joint

Even though finger joint has a number of demerits in the actual performance, it is largely used due to its low noise emission and therefore comparatively comfortable driving experience.

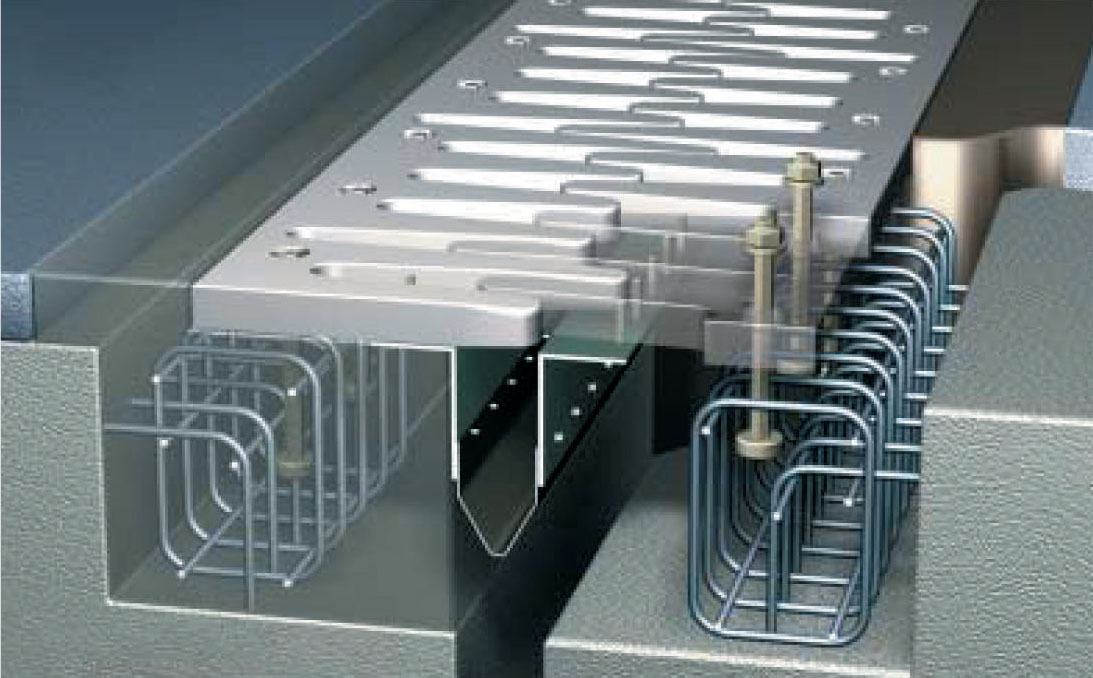

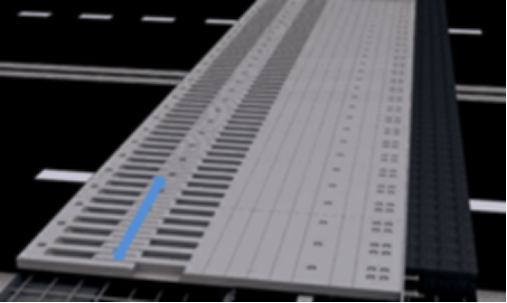

According to AASHTO Bridge Design Specifications and European code ETAG 032, finger joints can be broadly grouped into 2 types, cantilever-toothed type and supported-finger type, as illustrate in the following images.

Cantilever structure (joint stands right in the middle) Supported structure (longer finger plate crosses the beam gap)

The cantilever-toothed finger joint moves right in the center of the structural gap. Both sides are symmetrical and finger plates at both sides are moveable along with the movement of the bridge structure. Fingers interlace at a minimum 20mm distance when the max. movement occurs. The head of finger plates shall be rounded for safety concerns.

For the supported finger joint, finger plates are classified into fixed plates and moveable plates. Fix plates are bolted into the substructure and moveable plates cross the structural gap when the movement takes place. Even at the max. movement, moveable plates are supported by the surface of block-out all the time. A good thing is it is safer to traffic and can accommodate much larger movement (up to 2000m) but has a huge potential problem of difficulties in getting rid of the easily accumulated debris around the finger plates (at the open area as long as the two finger plates are apart), even it is claimed to have a self-cleaning function by shaping the finger head like a shovel. It shall be more prudent to choose the supported structure.

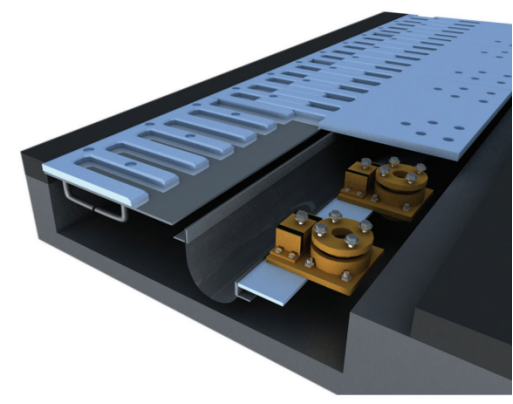

For large-span cable-stay bridges or suspension bridges, IEC develops a special design of supported structure which has spherical bearings installed beneath the moveable plates so it can meet larger rotation. This type has a unique name as “Multi-directional rotational finger joint” (code DXB), which will be elaborated in the subsequent paragraph.

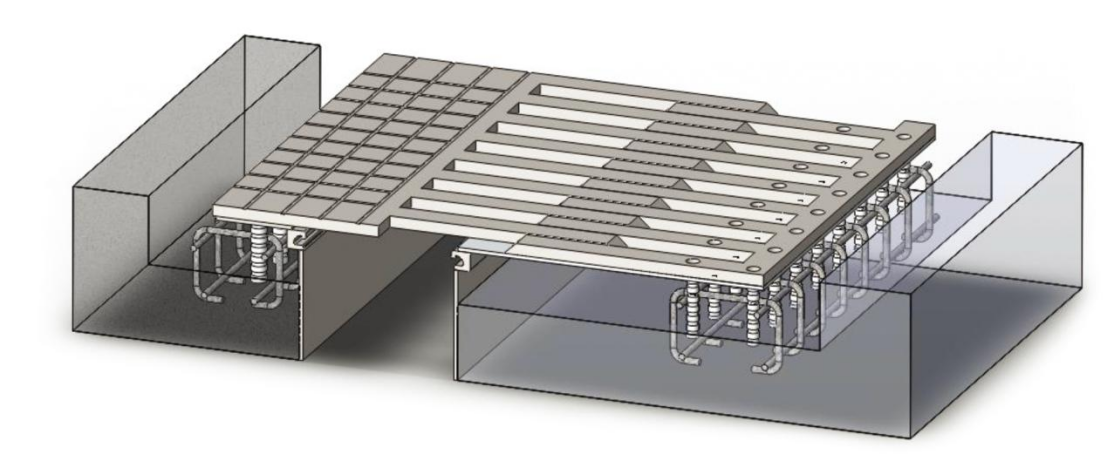

Either the cantilever structure or the supported structure has a lot of options in the designs. Selections largely depend on the safety concerns, movement/rotation requirement and the budget. Below images disclose some options of finger joints that IEC had supplied.

Numerous such finger joints have been supplied and installed by IEC in China

(mostly supported structure)

To place steel extrusions(steel profiles) beneath the finger plate has 2 good benefits. One is the assured strength resistance and the other one is the enhanced water tightness due to tight locking between rubber seal and the cavities of steel extrusions. (similar to stripseal or modular joints). Often, an extra layer of silicone adhesive is poured into the exposed voids between the finger heads.

Finger plates welded over steel extrusions. Silicone adhesive is used to reinforce effect of watertightness.

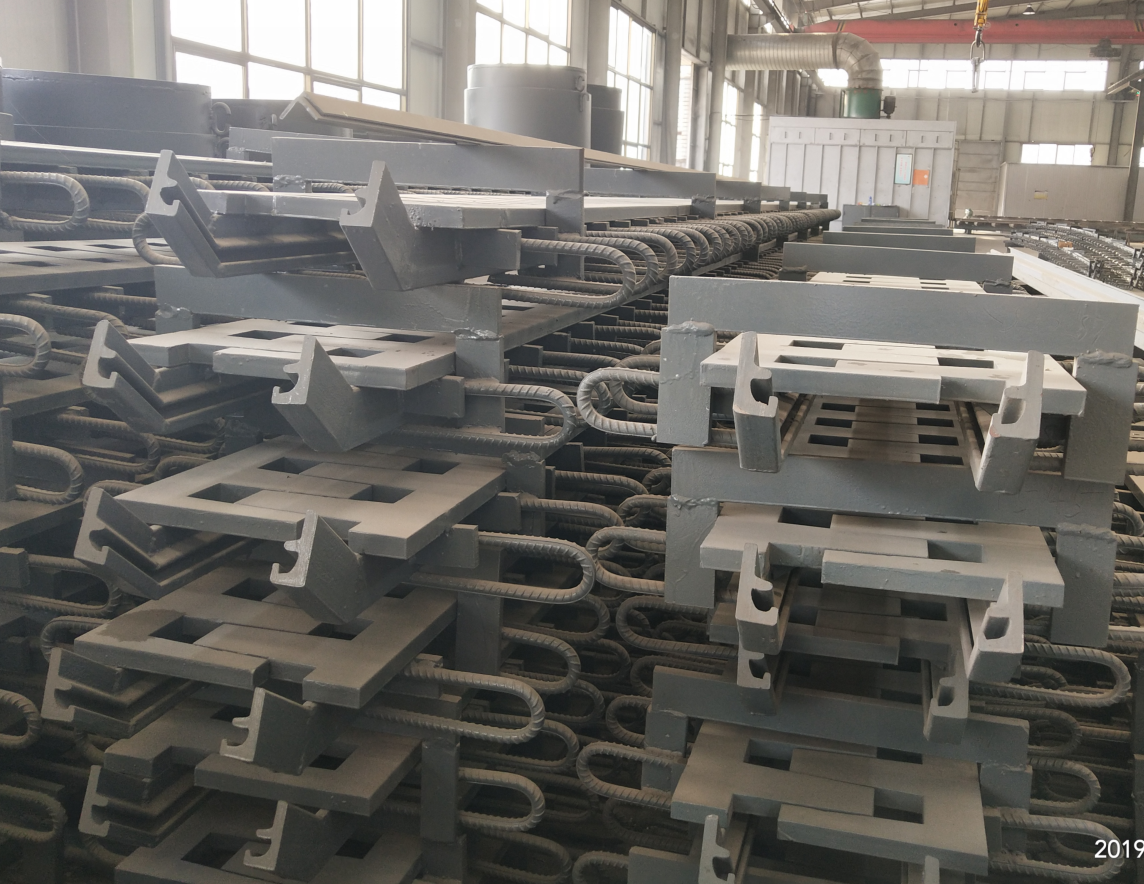

IEC’s workshop finished fabrication of finger expansion joint with 1440mm movement for project in Guizhou, China

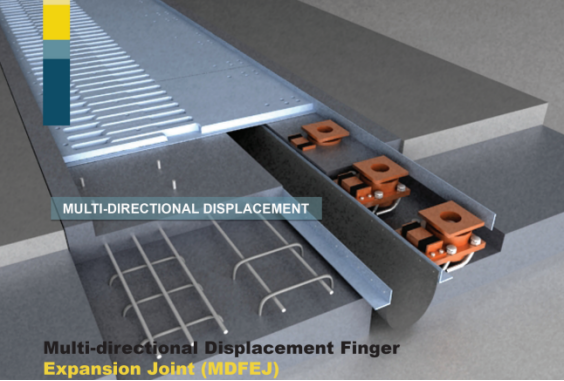

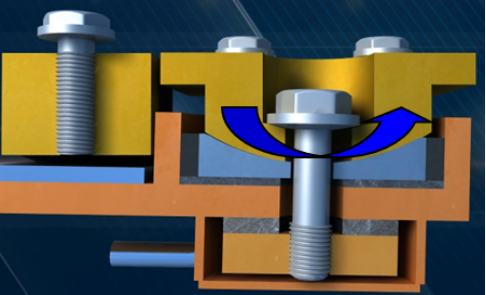

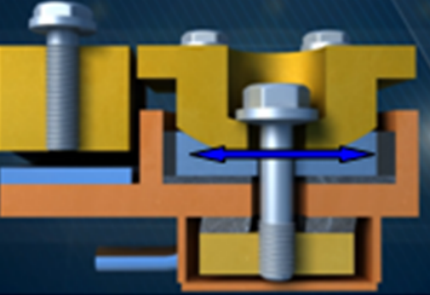

Multi-directional and multi-rotational finger joint, the DXB series innovated by IEC, combine the advantages of conventional finger joints and high-rotational spherical bearings. Testing shows that the maximal horizontal and vertical rotation movement can reach more than 0.05/rad.

Spherical bearings are placed beneath longer finger joint plates to cater for large rotational requirements (DXB finger joints)

Longitudinal displacement transversal displacement

Vertical rotation horizontal rotation

IEC supplied a 800mm movement DXB finger joint system for Brive over Huanghe River in Jiqing, Shandong, China

Consult IEC engineers for details.